Factory Fit-Out

If you were told your business premises and manufacturing HQ will be demolished in six months’ time, what would you do?

That’s what happened to our client, a high-volume printing company located near Heathrow. Having operated from the site for over 40 years, being told their landlord was about to redevelop the whole site and demolish the building presented an urgent challenge with a lot of potential stress and business interruption.

Questions and Challenges for a Business Relocation:

- Where to find suitable new commercial industrial premises?

- What is an acceptable location for the existing workforce with good transport links and close to our client base?

- How much sq.ft factory floor area, warehouse storage, and office space do we need?

- How much is rent and business rates for an industrial unit?

- How much Electrical Supply Capacity do we need to suit our production machinery?

- How to get the new industrial building fitted out electrically and mechanically ready to move production facilities while avoiding downtime?

Whilst we can’t help with every one of those questions, as trusted electrical contractors based locally between Bracknell, Wokingham and Reading, Matt Browning Electrical provides a full design and installation service for commercial industrial premises and has experience of manufacturing and production sites spanning over 30 years.

Initial Enquiry

This project began with an enquiry from the company’s Finance Director explaining the situation and asking if we could quote for the electrical work. We presented a case study of another similar factory fit-out project we carried out previously, and later set up a meeting with Scott, the Managing Director.

Pricing and Design

Time was limited and a potential new location had just been identified. We arranged a survey of the existing site to learn about the company’s operations and production processes. Surveying their current arrangements and details such as production machines, layout, heating and lighting levels enabled us to establish requirements for the new site. The proposed new site was a recently vacated warehouse presented as a basic shell & core specification. We undertook a fact-finding survey visit and with a 1-week deadline we prepared initial layout drawings to design & cost the electrical fit out.

We provided a fully quantified fixed price proposal to provide new electrical distribution, machine and small power supplies, lighting, heating, and interior fit-out. This method clearly establishes what we will provide and how much it will cost – giving our clients clarity and certainty.

Feedback from our client was positive - citing the comprehensive detail which instilled confidence that we had understood the brief. For us, with Matt’s background in manufacturing engineering, we could see that production was the priority as the key driver of the business - and at the same time this was an opportunity to improve process layouts and support facilities when compared to the old site.

“The owners of the company were really impressed by the level of detail in your quotation which reassured us that you knew exactly what we needed”

Project Start

With our proposal accepted, the team from Matt Browning Electrical were scheduled to commence work on site in August.

Machine positions and layout of the factory floor were marked up for client approval – seeing the physical layout on site rather than on drawings provides an opportunity for last minute discussion and adjustments.

As a responsible company, NICEIC Approved Contractor, and a member of the Electrical Contractors Association, we provide detailed risk assessment and method statements (RAMS) to accompany our work. This helps us design and plan the work so it can be carried out safely in practical terms and communicate this plan to our team, our client, and other stakeholders.

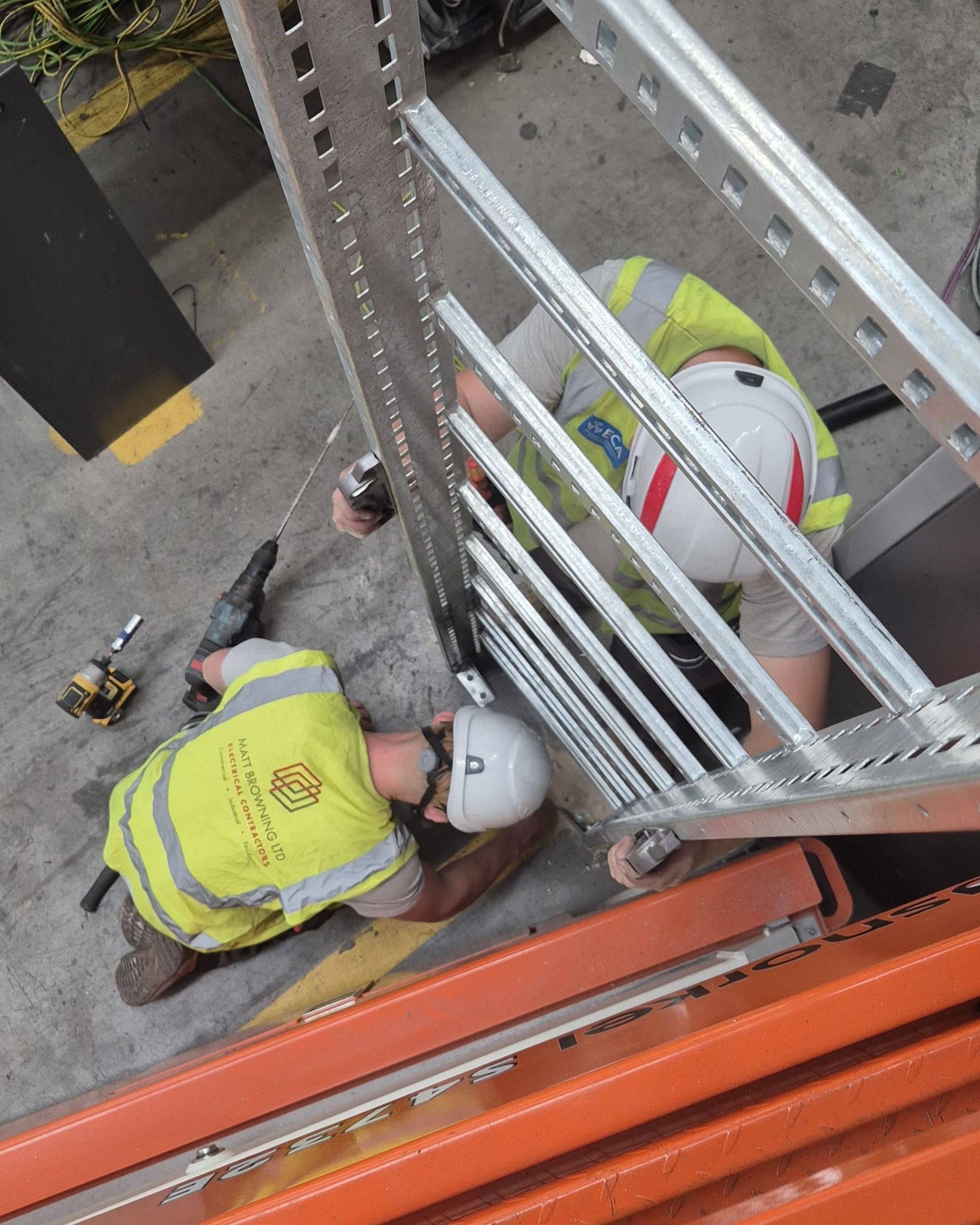

Cable Containment

Primary cable containment was the first milestone to complete. We designed and installed an overhead cable ladder system to deliver power distribution to large machines and local distribution boards. Installed at 4m height, this maintained access for forklift truck movements and machine installations, while enabling drop down posts and frames to feed small machines and workstations.

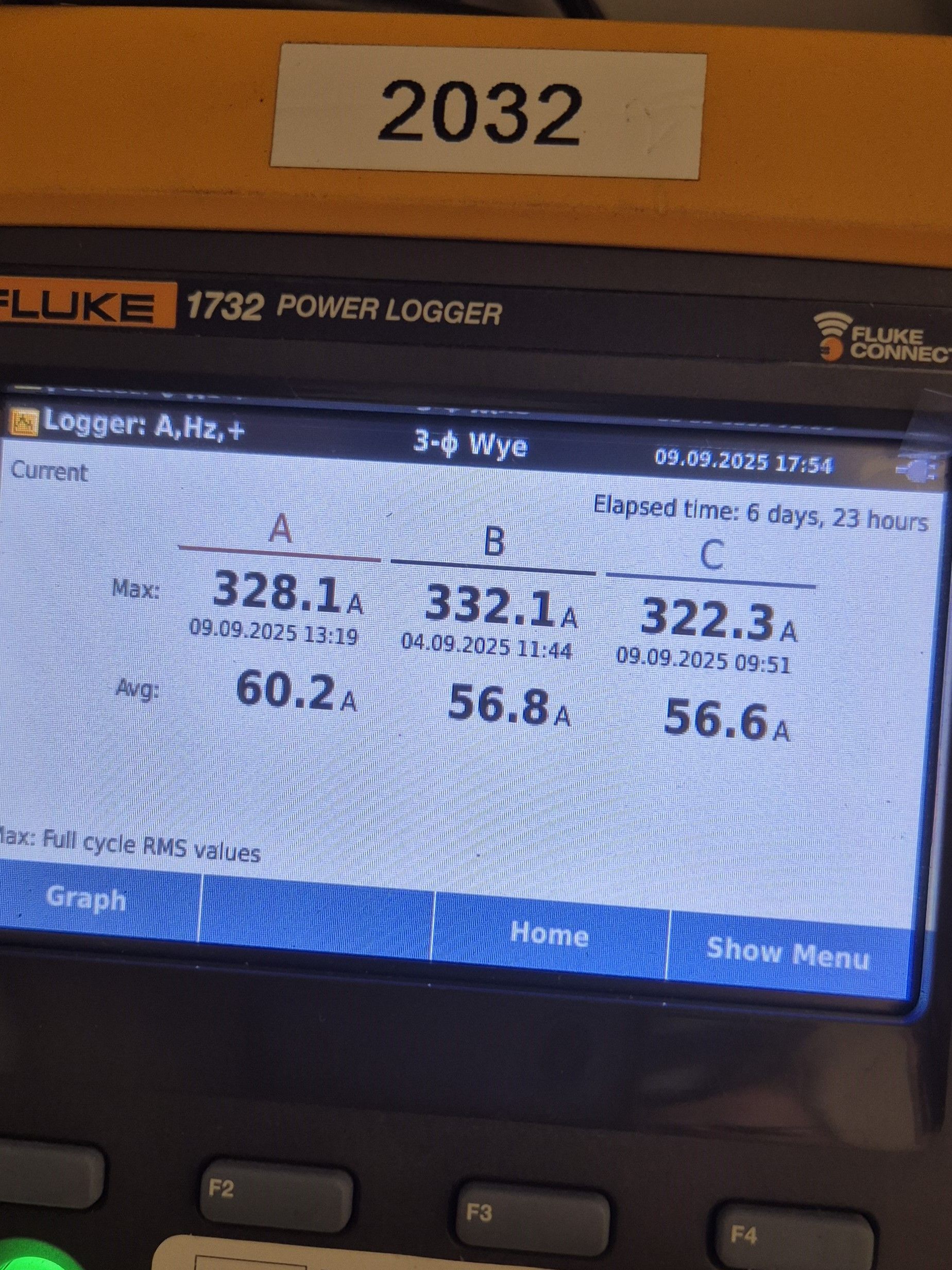

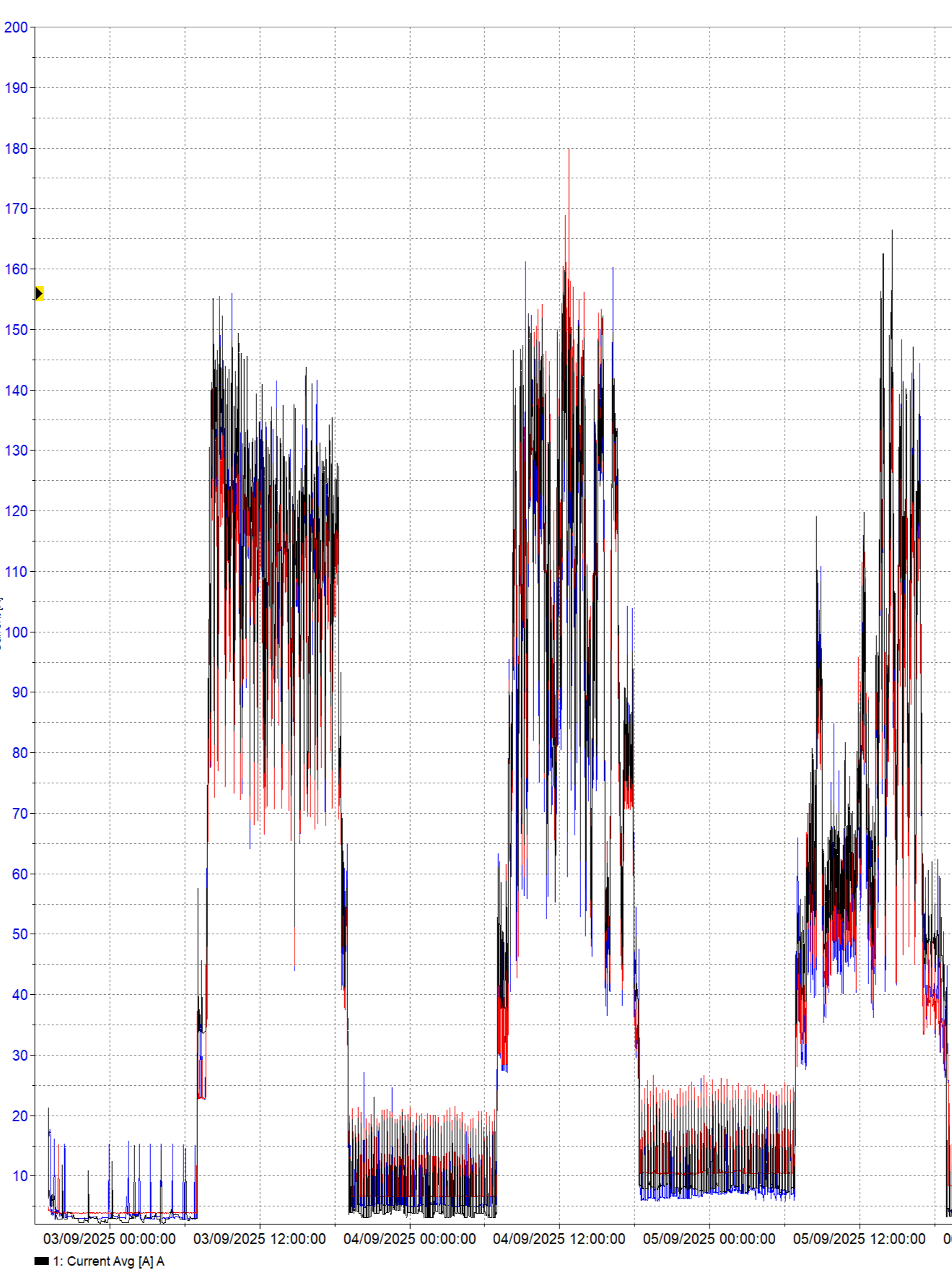

Electrical Supply Capacity

Authorised supply capacity and fusing at the new building was assessed by our team at the earliest opportunity, and as part of that process, we carried out a load study at the old site - monitoring maximum demand and load characteristics over a 1-week period. This enabled us to determine that a supply capacity increase was required at the new site to accommodate existing and new production machine loads. Working with SSEN, we coordinated and implemented this supply increase as part of our work.

Electrical Distribution & Cabling

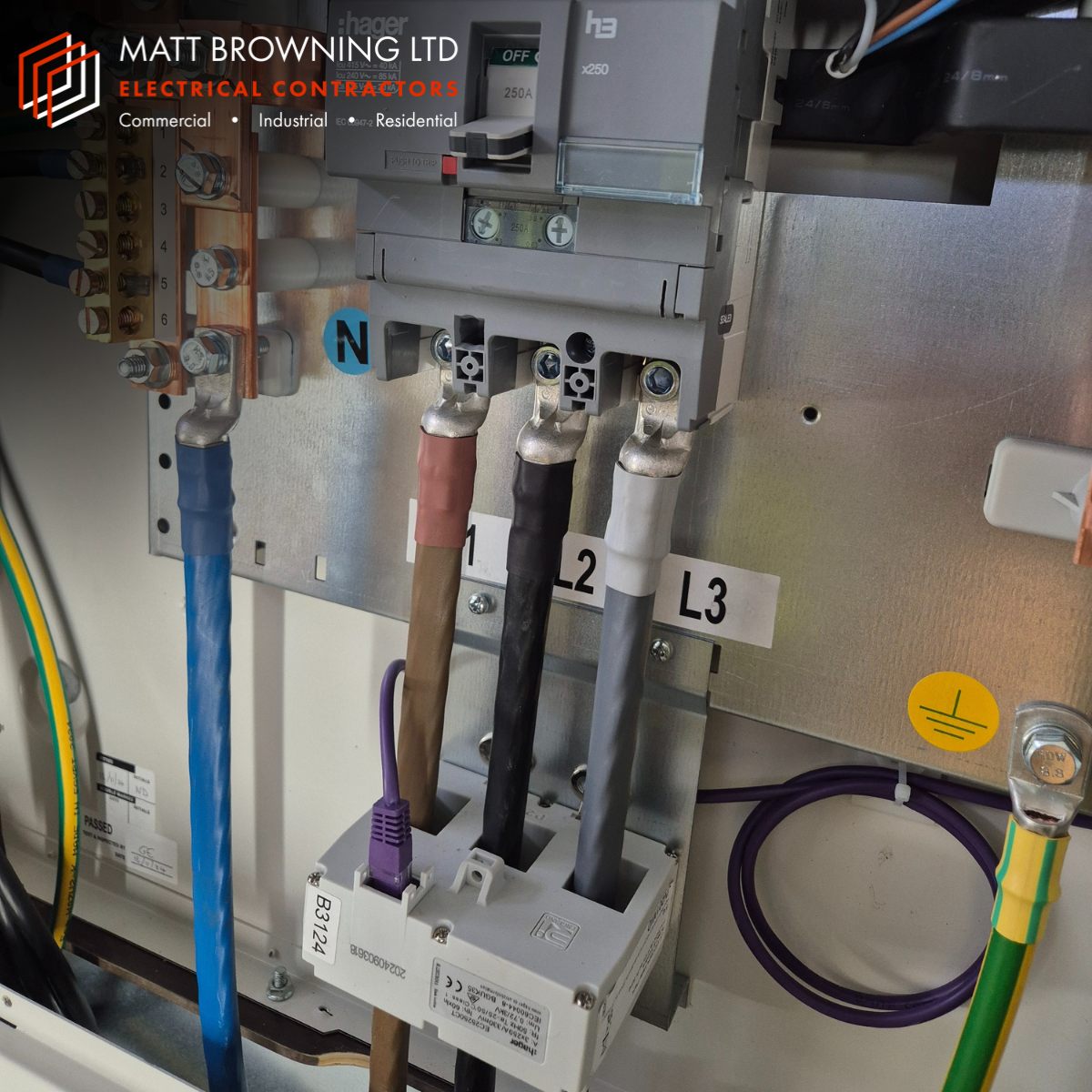

Our team replaced old electrical distribution boards with a Hager 630A 3-phase panel board - providing 200A outgoing feeds to larger machines and six new distribution boards for building services and production areas. With detailed design & planning beforehand, our electricians prefabricated the cable trunking and distribution board assemblies in advance. This ensured that once the incoming supply was de-energised, we could strip out and replace the primary distribution boards efficiently to get core building services such as security, access control, and fire alarm systems back up and running. That’s always a satisfying moment for our team, who take pride in delivering our projects to a high standard and on schedule.

Next, our electricians pulled in the SWA distribution cables, all glanded and terminated to deliver power across the factory. Existing distribution boards for office areas were also replaced to provide upgraded circuit protection including additional protection by 30mA RCD and Surge Protection for enhanced safety and reliability. At Matt Browning Electrical we take pride in the details with full testing & certification, circuit schedules and labelling provided at every distribution board – making future operation & maintenance easy and safe.

Lighting Scheme

Lighting was carefully considered as our client required a high lux level with shadow free coverage for quality control inspection across the production process. We know from other manufacturing clients we serve that high bay LED lighting can be problematic causing excess shadows, glare and non-uniform coverage. As a result we designed and installed low level linear lighting suspended just below the cable ladder system. Utilising a busbar trunking system (tried & tested on other projects) helped us get the new lighting system installed quickly whilst providing flexibility for future layout changes.

Self-test open area emergency lighting was also installed as part of the new lighting scheme – ensuring safety in the event of power failure. As the project progressed, we received great comments from our client’s production staff coming to see the new site and appreciating the standard of lighting. For us it’s always rewarding to get good client feedback – both from management and from the people on the ground who will be working in the area. Delivering quality lighting that clearly makes a difference both in terms of performance, reliability and energy costs – especially when compared to the ageing and obsolete fluorescent lighting at the old site.

Milestones and Machine Connections

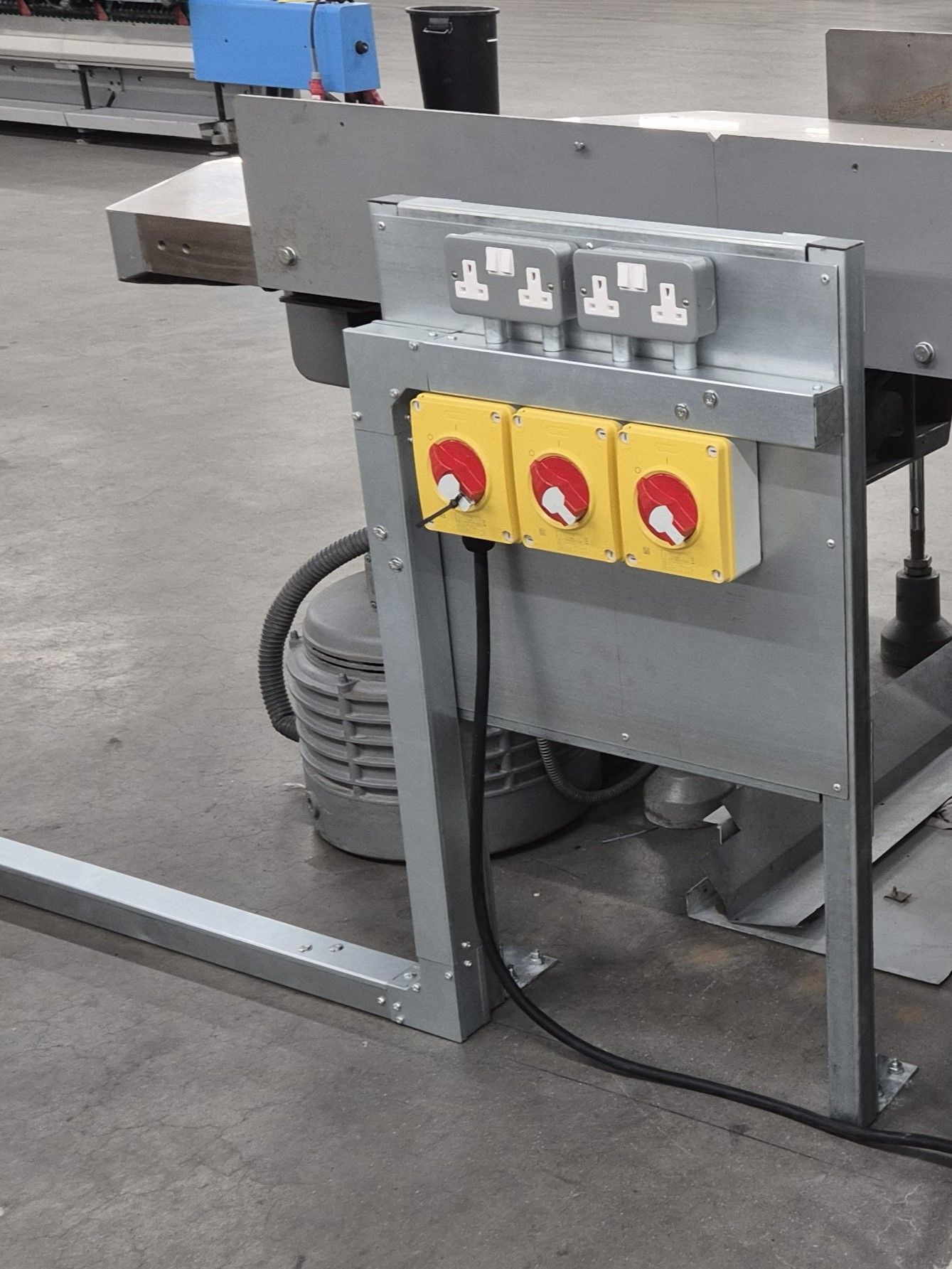

Working to our project plan, we delivered each element of the project on schedule as promised – providing confidence for our client that the site was ready to start moving production from their old premises. A combination of existing production machinery and some new machines were installed and connected – with the largest being a Heidelberg 6-colour printing press fed from a 200A TPN supply using 95mm2 SWA cable on the cable ladder. Custom fabricated drop-down posts were used to supply workstations with 13A sockets and isolators for machine connections, as well as provision of compressed air / water connections where required.

Our team also coordinated interior alterations as part of the package to accommodate a pre-press plate setting room and staff kitchen within the undercroft area – all delivered on schedule and coordinated through one point of contact to help our client.

Inspection & Testing

During and on completion of the installation, our electricians inspected and tested their work to ensure compliance with our initial design and BS7671 Electrical Wiring Standards. Full electrical certification was provided, together with circuit charts and labelling of equipment. This isn’t just paperwork or box ticking, it checks and verifies safety, reliability, and performance in normal operation and in fault conditions – helping our client demonstrate the safety of their site. Not only that, it also enables quicker and safer planned or reactive electrical maintenance and future Electrical Installation Condition Reports or fixed wire testing.

Project Completion

By the end of October, our team successfully completed all quoted works on schedule, as per quote, and to a high standard.

As an electrical contractor, we love hitting our project milestones and delivering a high-quality outcome that exceeds our clients’ expectations. Observing newly printed work going through the production process at the new site is a satisfying conclusion to the project.

Can we help you?

Do you need help with a business relocation or expansion? Whether it’s a new electrical supply for a single machine, or a complete relocation or fit out project for your office, warehouse or factory, we’d love to provide a solution.

At Matt Browning Electrical our friendly team is always ready to discuss your requirements and provide advice where needed. Based in Berkshire near Bracknell, Reading, and Wokingham, we cover the Thames Valley and M4 M3 areas of southern England.

Give us a call or submit an enquiry form today!

Initial advice, surveys, and quotations are always complimentary and no-obligation. Depending on the size of your project, we may quote to provide more extensive design services if required.

We also offer planned and reactive maintenance services as well as fixed wire testing (EICR inspections) to keep existing installations fully operational and compliant – for your peace of mind, productivity, and safety – not only that, it can help reduce your dilapidations liability on a commercial building lease.